Electro Hydraulic Thruster Brakes

Electro Hydraulic Thruster Brakes

Introduction

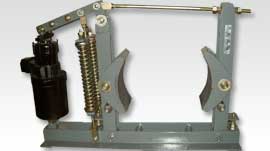

Thruster brake is a device used to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the brake drum and compressing of the spring is done by thruster.

Assembly and Function

A thruster shoe brake has a pair of cast iron shoes which are lined up with friction pads. The shoes are hinged on main arm and side arm of the brake, each of them have a hinge pin fitted in the base. They are connected to each other on top by a tie rod, which is hinged in the main arm and locked to the swivel block in the side arm, by a lock nut. A crank lever is hinged on the main arm and the other end is fixed to the top clevis of the thruster by a hinge pin. A brake spring is fixed on the main arm and is pre-loaded by a locknut on the lever. The pre-tension in this spring decides the braking torque. The thruster is fitted on the base by a hinge pin. When the thruster is not energized, the brake shoes are pressed on the brake drum fitted on the drive motor shaft and hold it under the effect of braking force provided by the spring. In such condition, the brake is applied and the drum cannot rotate. As the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring. Simultaneously, the brake lever on the other side of the wheel (Brake Drum) is retracted. When the first lever reaches the stop on the brake base member the brake lever at the thruster begins to move, releasing the brake drum.

Technical Specification

|

Model No. |

Drum Dia |

Braking Torque (KG.M) |

Thruster Details |

Length (max) |

Width (max) |

Height (max)

|

||

|

Model No. |

Force (KG) |

Stroke (MM) |

||||||

|

RI-EHTB-100/18 |

100 |

6 |

RI-EHT-18 |

18 |

51 |

425 |

140 |

430 |

|

RI-EHTB-150/18 |

150 |

9 |

RI-EHT-18 |

18 |

51 |

550 |

200 |

450 |

|

RI-EHTB-160/18 |

160 |

10 |

RI-EHT-18 |

18 |

51 |

550 |

200 |

450 |

|

RI-EHTB-200/18 |

200 |

20 |

RI-EHT-18 |

18 |

51 |

675 |

200 |

450 |

|

RI-EHTB-200/34 |

200 |

32 |

RI-EHT-34 |

34 |

51 |

763 |

225 |

575 |

|

RI-EHTB-250/18 |

250 |

35 |

RI-EHT-18 |

18 |

51 |

725 |

200 |

525 |

|

RI-EHTB-250/34 |

250 |

42 |

RI-EHT-34 |

34 |

51 |

850 |

225 |

575 |

|

RI-EHTB-300/18 |

300 |

42 |

RI-EHT-18 |

18 |

51 |

850 |

225 |

575 |

|

RI-EHTB-300/34 |

300 |

62 |

RI-EHT-34 |

34 |

51 |

850 |

225 |

625 |

|

RI-EHTB-400/46 |

400 |

90 |

RI-EHT-34 |

34 |

51 |

1000 |

238 |

675 |

|

RI-EHTB-400/68 |

400 |

110 |

RI-EHT-46 |

46 |

51 |

1000 |

238 |

675 |

|

RI-EHTB-500/46 |

500 |

190 |

RI-EHT-46 |

46 |

51 |

1525 |

262 |

700 |

|

RI-EHTB-500/68 |

500 |

290 |

RI-EHT-68 |

68 |

76 |

1525 |

262 |

700 |

|

RI-EHTB-600/68 |

600 |

350 |

RI-EHT-68 |

68 |

76 |

1625 |

262 |

775 |

- Rugged design

- Consistent braking performance

- Robust in construction

- Long life

- Trouble free maintenance

- Easy in service